IoT mcframe

Designed using hands-on experience and knowledge acquired in the field, mcframe IoT is aimed at improving the overall efficiency of industrial plant systems

mcframe IoT series digitizes explicit know-how and experience acquired in the field, and combines this data with information obtained from the planning layers such as ERP to provide solutions aimed at helping manufacturing plant managers make optimal decisions and take the right actions.

Manufacturing companies across several countries and regions of the world have chosen to implement the mcframe IoT solution because it helps them achieve a “digital factory” with improved efficiency of in-house manufacturing, as well as a “digital value chain” that enhances value for their customers, both of which are needed to establish new businesses and new revenue sources according to the “digital business model.”

In addition, mcframe IoT:

○ Promotes the efficient usage of resources

○ Improves production efficiency

○ Is capable of displaying production results through IoT channels

○ Analyzes personnel management and improves performance

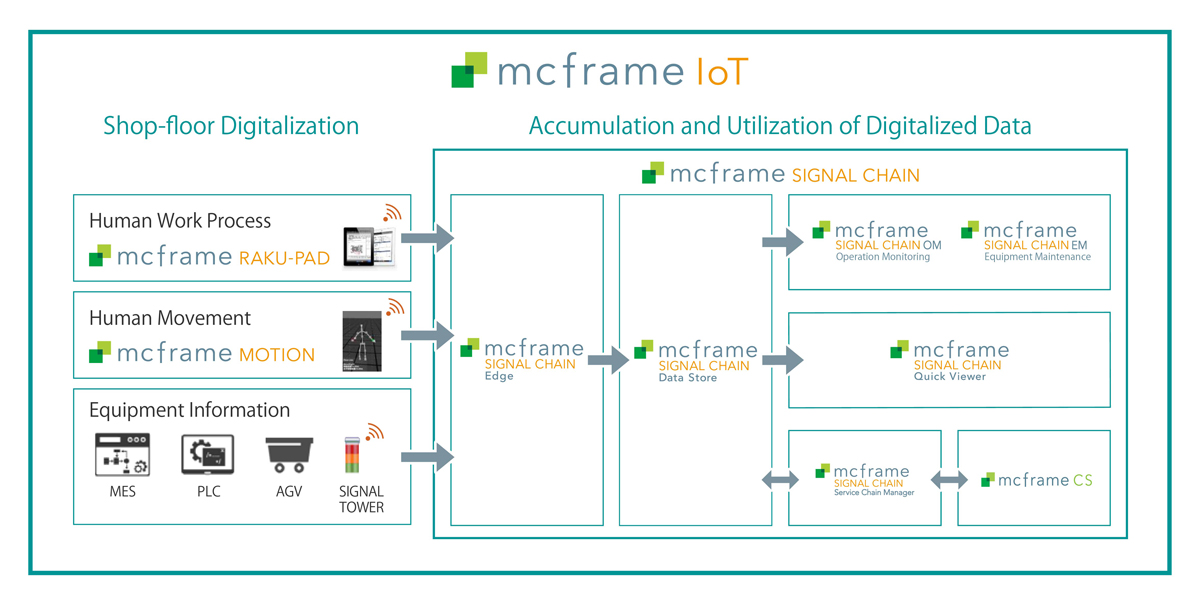

B-EN-G’s IoT Products

1. mcframe RAKU-PAD

The mcframe RAKU-PAD is an on-site paperless solution designed for factories, warehouses, and more with functions that support data recording, analysis and utilization for on-site improvement. It employs a handy tablet that delivers superior mobility, operability and visibility, and with this you can convert data from hand-written paper forms into iPad data entry forms.

2. mcframe SIGNAL CHAIN

The mcframe SIGNAL CHAIN is a wireless system that automatically collects usage information from new and old machines/equipment using IoT devices attached to the signal antenna. This collected data then helps you to visualize the real operation of the equipment involved, as well as plan their maintenance.

4. mcframe OEE

The mcframe OEE is a software tool that receives data from various sources on the production line such as sensors, PLCs (Programmable Logic Controllers), tower lights, and smart boxes. After acquiring information from all of these sources, mcframe OEE pools them together on the cloud and uses them to calculate the overall equipment effectiveness (OEE) of each of the equipments involved.

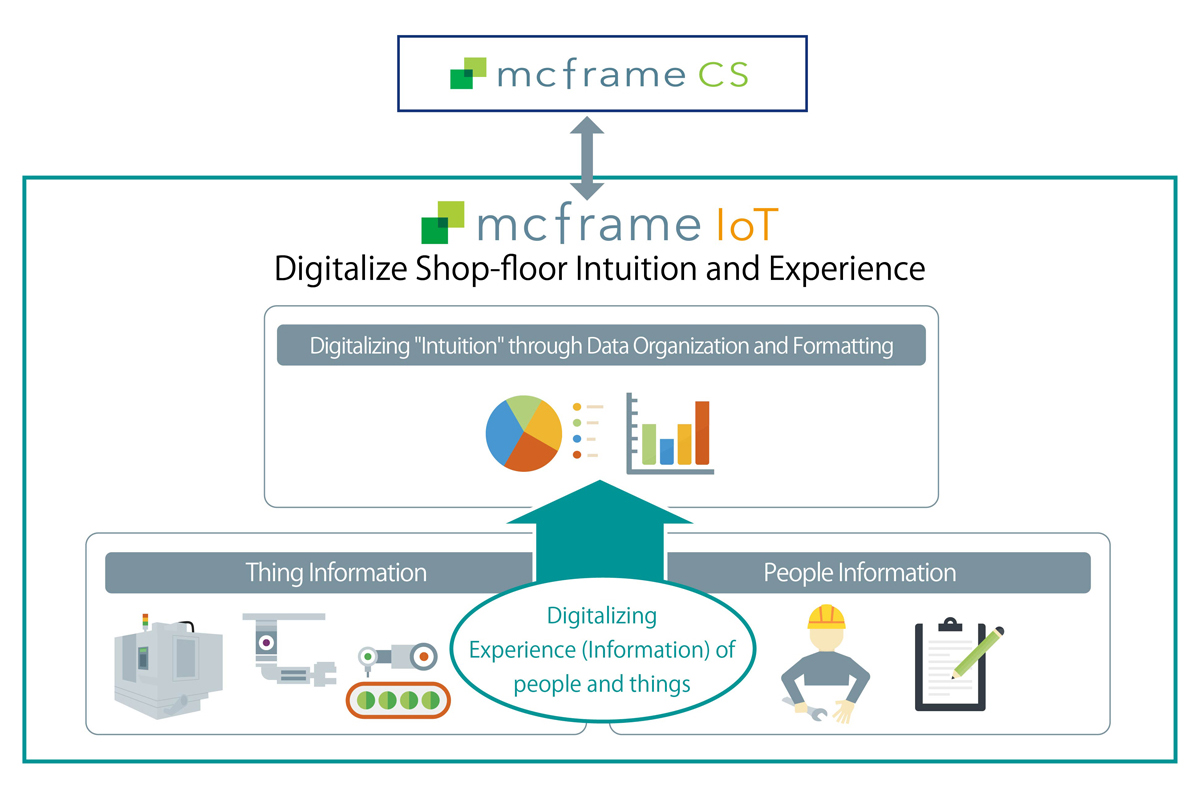

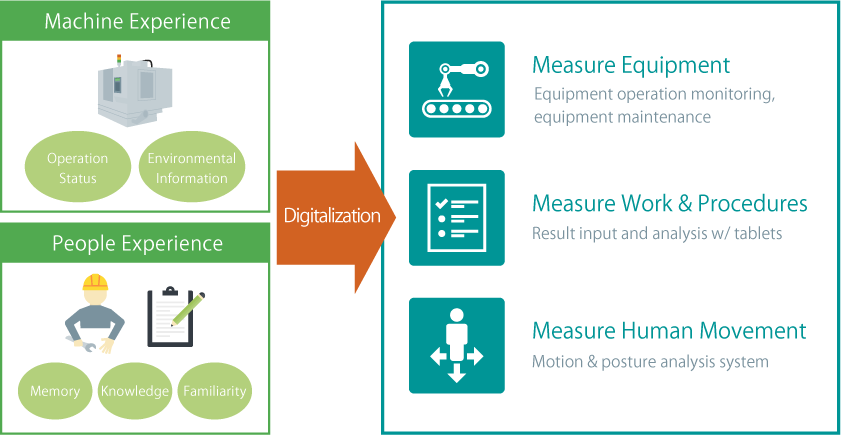

Digitizing Experience

In the manufacturing industry it is usually the case that “the skills and knowledge of experts cannot be shared /inherited in the field” and “the method of inputting achievements differs depending on the person in charge”; this level of personalization tends to reduce productivity because individual experience is not made available for use in a tangible form.

It is also usually the case that machine information which should be regularly gathered for use as a standard for measuring the health condition of the site, and for improving productivity, is rarely frequently collected or used.

The mcframe IoT series offers your firm a convenient way of gathering the experiences of people as well as machines, and converting them into data which is a tangible asset that can be used to improve many business processes.

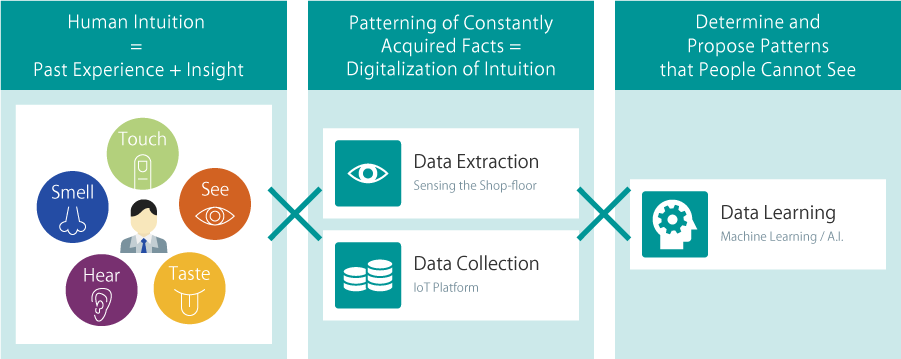

Digitizing Intuition

It is so often the case that a person’s intuition is sharpened by continuous success and failure experiences, and that this intuition can be utilized effectively by the addition of insights relevant to the situation. However, the amount of information that people can accumulate and the time it takes them to gain these insights is limited in most cases, and as a result making the right decisions always can be difficult.

mcframe IoT series provides a platform that helps managers make decisions as a digitized "intuition" by organizing, shaping, and giving them access to information constantly acquired from people and machines and combined with various other relevant data. These are shared as explicit knowledge, and eventually evolve into a more powerful business tool through the continued addition of other peoples’ knowledge, and the optimization of this knowledge for use in various situations.

Impact in Various Manufacturing Companies

As a group of products designed for the purpose of acquiring site information from people and machines, converting this information into digital data, as well as accumulating and utilizing the acquired data, the mcframe IoT series have been successfully implemented in many companies to achieve the following results:

One-Stop Support for mcframe Manufacturing IoT

Everything about manufacturing IoT does not end with the introduction of the software into your company. After introduction, there will be other aspects to consider such as the kind of effect to expect, and tasks to complete including the calculation of costs for trial, assembly of sensors on site, implementation of operation test, as well as effect measurement and evaluation, all of which require both hardware and software to achieve.

B-EN-G also specializes in providing one-stop support with “engineering ability” for companies that have chosen to implement our manufacturing IoT solutions, helping them adapt successfully and get the results they desire out of them.

B-EN-G also specializes in providing one-stop support with “engineering ability” for companies that have chosen to implement our manufacturing IoT solutions, helping them adapt successfully and get the results they desire out of them.

Benefits of mcframe IoT to the manufacturing industry

Promotes machine maintenance planning for good production efficiency

mcframe IoT improves connectivity, communication efficiency, flexibility, time utilization, and cost savings when used to plan work in industrial plants. Companies that adopt it will benefit from IoT in reducing their production costs through predictive maintenance, monitoring of machine status, avoiding system downtime, improving safety, and improving operational efficiency.

Removes any barriers of time and place

Because IoT is driven by the internet, it makes it possible to connect distant things closer together. An example of this in the manufacturing industry is that users can track the operation status of machines or production lines. Even if the factory is in a different province or in different countries, this tracking can still work with mcframe IoT, unlike with humans. This suggests that using IoT can break the barriers of time and place.

Helps reduce both direct and indirect costs

IoT is an innovation to help increase industry efficiency. The introduction of mcframe IoT means that productivity data can be saved using tablets instead of paper, and this reduces direct costs associated with paper costs and document storage costs, or indirect costs such as the cost of production opportunities. For example, mcframe IoT can be used to calculate OEE to help analyze machine productivity, and reduce the chance of unseen wastes that may occur in the production process.