mcframe OEE

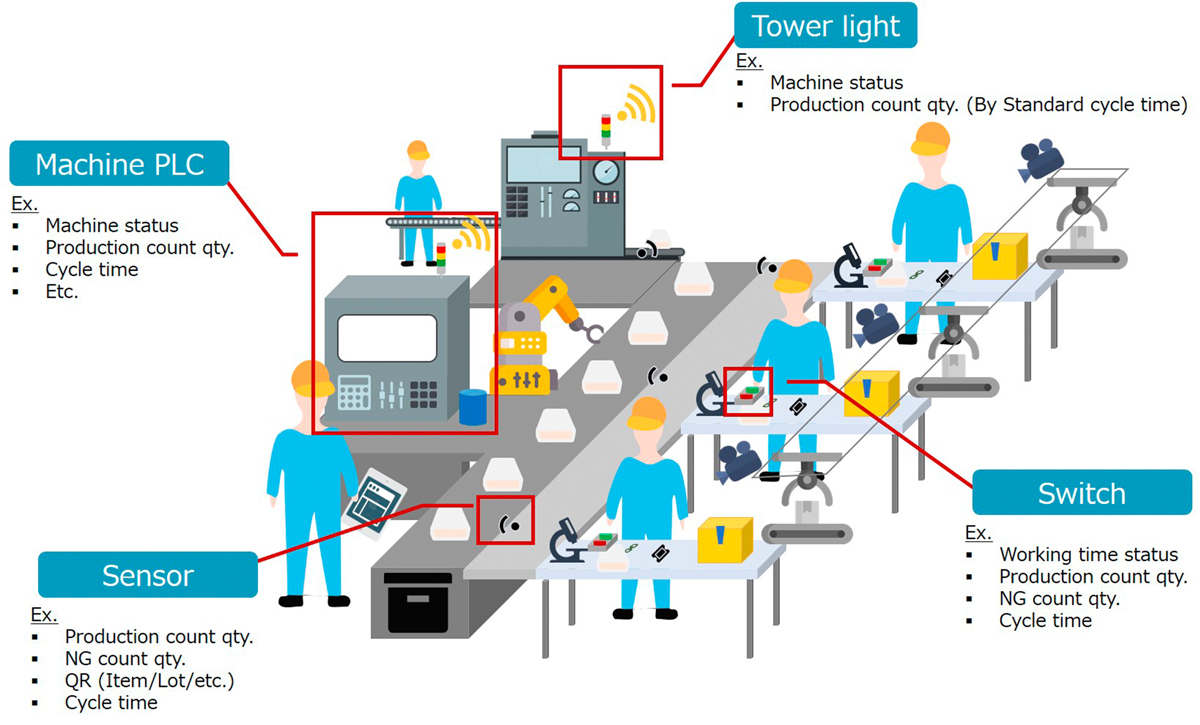

is a software tool that receives data from various sources on the production line such as sensors, PLCs (Programmable Logic Controllers), tower lights, and smart boxes. After acquiring information from all of these sources, mcframe OEE pools them together on the cloud and uses them to calculate the overall equipment effectiveness (OEE) of each of the equipments involved.OEE is the globally accepted standard for measuring manufacturing productivity; it is also the single best metric for identifying losses, improving manufacturing equipment productivity, and benchmarking progress. Through the measurement of OEE as well as the underlying losses, manufacturing firms gain useful insights on how to improve their manufacturing processes and increase productivity.

Measuring Overall Equipment Effectiveness

The measurement of OEE is regarded as a manufacturing best practice. The production line data acquired by mcframe OEE software can be used to measure 3 underlying factors of overall equipment effectiveness:

Availability

Availability accounts for Availability Loss (any events that stop planned production for a significant length of time), and is measured by recording the duration of Planned and Unplanned Stops. An Availability score of 100% means there is no Stop Time and the process runs as quickly as possible when it is running.

Performance

Performance accounts for Slow Cycles and Small Stops, or Performance Loss (factors that cause the running process to do so at less than the maximum possible speed). Performance is measured by comparing Actual Cycle Time (or Actual Run Rate) to Ideal Cycle Time (or Ideal Run Rate), and a 100% Performance score means that the process runs as fast as possible when it is running.

Quality

Quality accounts for Defects/Quality Loss (parts that need Rework because they fall short of quality requirements). A Quality score of 100% indicates there are no Defects (only Good Parts are being produced). The OEE program measures Quality usually by tracking Reject Parts.

OEE takes all losses into account and identifies the percentage of manufacturing time that is actually productive. Getting an OEE score of 100% will indicate that your firm is manufacturing only Good Parts, as fast as possible, and with no Stop Time.

Availability accounts for Availability Loss (any events that stop planned production for a significant length of time), and is measured by recording the duration of Planned and Unplanned Stops. An Availability score of 100% means there is no Stop Time and the process runs as quickly as possible when it is running.

Performance

Performance accounts for Slow Cycles and Small Stops, or Performance Loss (factors that cause the running process to do so at less than the maximum possible speed). Performance is measured by comparing Actual Cycle Time (or Actual Run Rate) to Ideal Cycle Time (or Ideal Run Rate), and a 100% Performance score means that the process runs as fast as possible when it is running.

Quality

Quality accounts for Defects/Quality Loss (parts that need Rework because they fall short of quality requirements). A Quality score of 100% indicates there are no Defects (only Good Parts are being produced). The OEE program measures Quality usually by tracking Reject Parts.

OEE takes all losses into account and identifies the percentage of manufacturing time that is actually productive. Getting an OEE score of 100% will indicate that your firm is manufacturing only Good Parts, as fast as possible, and with no Stop Time.