mcframe RAKU-PAD

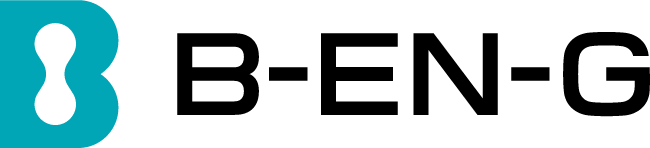

A paperless solution that accelerates on-site

improvement with data recording, analysis and utilization

mcframe RAKU-PAD

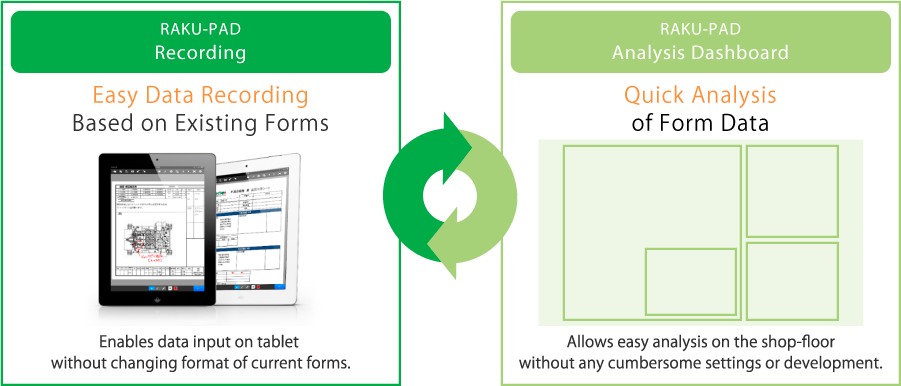

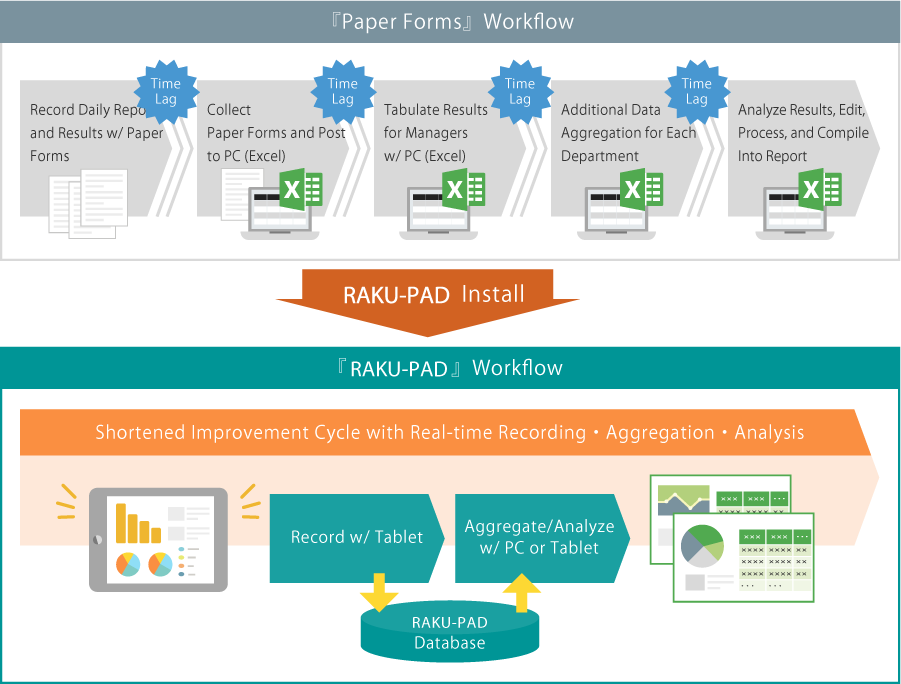

is an on-site paperless solution designed for factories, warehouses, and more. It employs a handy tablet that delivers superior mobility, operability and visibility, and with this you can convert data from hand-written paper forms into iPad data entry forms.

Going beyond simple and quick data entry, mcframe RAKU-PAD offers other software tools created to help shop floor operators achieve optimal operational efficiency and quality, as well as simplify troubleshooting by leveraging database-driven analysis tools developed using our wealth of experience with manufacturers' workplaces.

The solution allows you to visualize real-time conditions as well as analyze problems with various graphs based on Japanese quality control methods. It also provides you with the option of sharing for utilization, valuable knowledge obtained through accumulated historical data. This knowledge can be shared in the form of drawings, photos and workflow charts relevant to each operation.

Key Selling Points