Business Intelligence

Intelligent solutions to help companies bridge the gap between systems while utilizing a data-driven approach to decision-making in the process

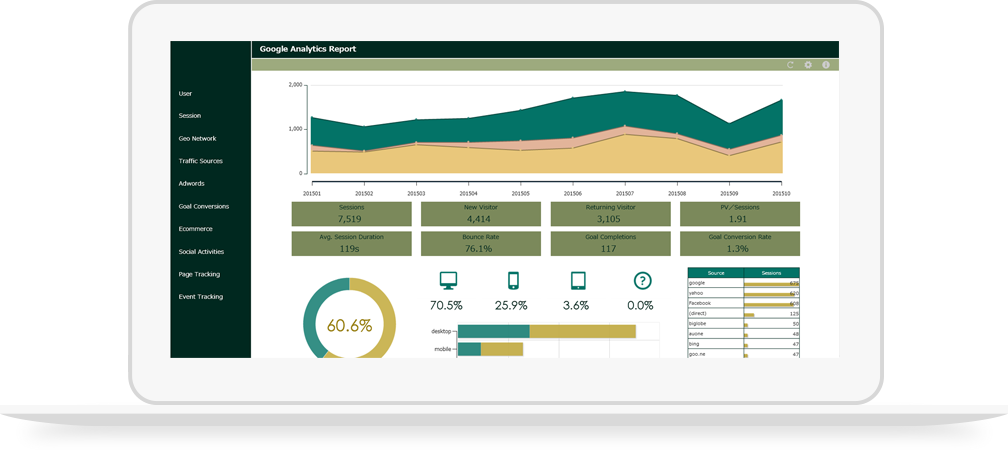

Business Intelligence (BI) takes advantage of software and services to convert raw data into actionable insights organizations can rely upon while making tactical and strategic business decisions. BI tools can be used to improve data analysis in companies because they are capable of accessing and analyzing huge and complex data sets, and presenting analytical findings which represent detailed intelligence about the state of a business through reports, summaries, graphs, charts, maps, and dashboards.

With the level of complexity inherent in many industries today, it is important to be able to make meaningful data connections between every aspect/process such as supply chain, machine operation, and logistics. As analytics that provide insights into a wide range of business processes, BI is an effective way of making these much needed data connections which will then help you create meaningful, customized reports that promote a better understanding of your business activities and organization as a whole, and help you make informed business decisions in order to stay profitable and competitive.

For modern business owners, BI can represent the ability to:

○ Gain useful knowledge from big and complex data

○ Personalize their marketing and sales strategy

○ Identify and avoid bottlenecks in real-time

○ Optimize their business model

○ Remain competitive even in complex business environments

Business Applications

1. Supply Chain Management

BI solutions can be used to evaluate supplier performance on a regular basis, and these evaluations enable supply chain managers to maintain high quality standards, negotiate prices better, and ensure deliveries are carried out in a timely manner. BI facilitates freight cost monitoring as well by identifying changes in demand and supply, and analytics help you spot defective components on time so you can proactively take preventive measures.

2. Cost Management

To create quotes and estimates that are as accurate as possible you will first need to assimilate information from the entire production process, and BI solutions help you do just that. All through the production process you will also be able to trace job costs so as to obtain a true job cost.

3. Production Scheduling

BI solutions can be very useful in production because they empower you to create better schedules that are based on actual capacities, thereby reducing congestion in your production system. With these systems you can also analyze machine, workstation, employee and department capacity to determine how an efficient movement of jobs through your shop can be achieved.

4. Financial Management

To achieve an ideal quality of forecasting and planning, your budgets need to include operations, production, sales, fulfillment, and up-to-date financial figures. A BI system can help you develop such budgets. It can also help you create accurate financial and profitability models, as well as set performance goals through the analysis of information across multiple departments.

5. Inventory Control

With BI you can conveniently keep track of inventory use across jobs for better inventory management; you can also track turnover rates, product margins, and defectives, and this will help you do away with sudden material shortages and restock materials based on actual on-the-job demand to avoid interruptions during production.

Benefits of BI for Data-Driven Businesses

Increased manufacturing operations efficiency

As manufacturing is one of the most data-intensive industries with data coming from supply chain management, shop floor scheduling, accounting, shipping, delivery, and more sources, there has to be a way to sort out the useful from the non-useful. Our BI solution takes all the data generated by different departments in your company and converts them into a comprehensive and actionable form, allowing you to detect and correct errors in real-time, project the demand for raw materials, evaluate team performances, suggest corrective measures for appropriate allocation of scarce resources, and analyze several supply chain processes to ensure optimal efficiency is realized.

Better supply chain management

B-EN-G’s BI solutions provide useful insights into general supply, freight expenditures, and deliveries, giving you greater control over carrier performance, costs, and shipments. In other words, it helps you manage complex supply chain processes in a better way.

Minimal inventory costs and errors

Two of the most significant factors that pose a challenge to profitability in all trading, wholesales, and manufacturing businesses are overstocks and out-of-stocks. However these challenges can be overcome with BI which helps you easily keep track of inventory across times and locations, and calls attention to problems such as inventory turnover, product defects, as well as margins based on individual distributors.

Insight and oversight of financial processes

With B-EN-G’s BI solutions you can get insights into the usage of raw materials, sales, profit and loss, and these insights can empower you to improve your ROI by optimizing the usage of your resources. Being able to identify your cost-benefits means you’ll also be able to monitor all business operations and processes, control costs, and manage your value chain better.

Better decision making

Since BI tools are able to manage, store, and make information from multiple sources accessible and easily understood, they can be very useful for decision making. BI solutions can be used to present analysis, key business matrices, and KPIs (Key Performance Indicators) in a simplified manner; they can also be used to test ‘what if’ scenarios to project and analyze alternate strategies, thereby empowering decision-makers to make more informed and precise business decisions.

Improved quality assurance

With BI tools manufacturers can more easily carry out a thorough analysis of all production and QA processes, thereby revealing vital patterns and trends, correcting issues as promptly as possible, and gaining insight into the factors that determine how well products are made. All this positively impacts on product quality which, in turn, leads to better customer experiences.

IoT and BI for Manufacturing

IoT (Internet of Things) powers BI. This means that manufacturing companies that are currently leveraging IoT devices already have an easy means of obtaining the data they need to drive BI solutions.Once acquired, these data are fed into BI systems which process and transform them into actionable insights. With IoT and BI working side by side, certain processes can be automated to free up time for higher-priority tasks; activities and issues that previously would not be accessible to you in real-time also become available for you to access, control, and improve as promptly as possible, thereby increasing your business advantage.

Overall, an IoT infrastructure paired with BI delivers very useful intelligence to support improvements in process, makes your manufacturing operations more valuable, and ultimately increases profitability.